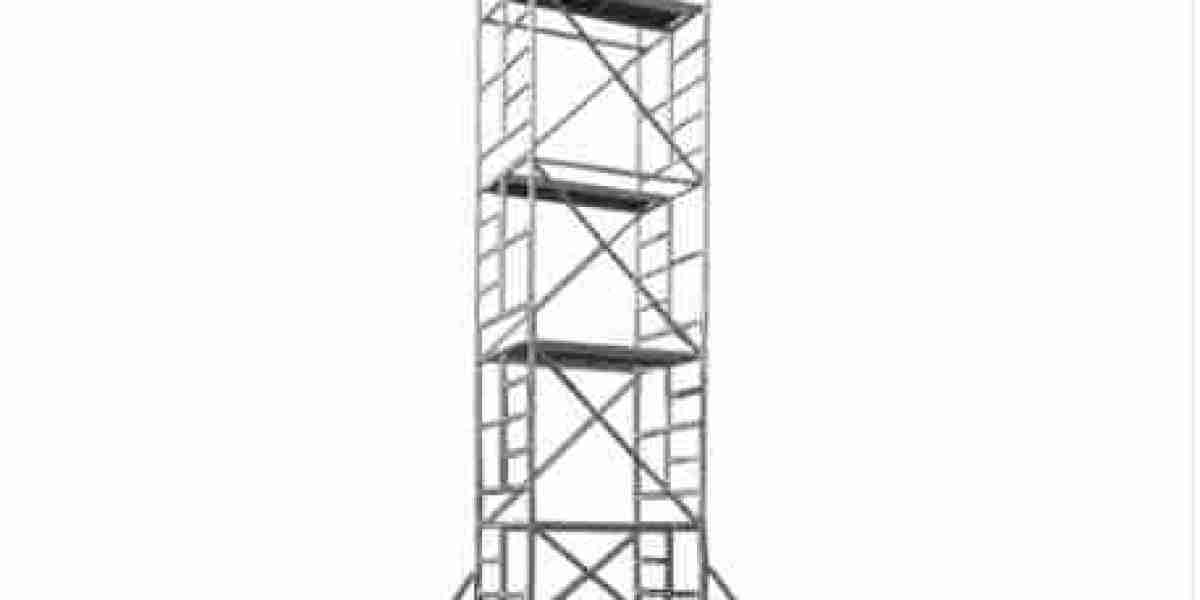

Aluminum scaffolding towers have revolutionized the construction industry with their lightweight yet sturdy design, offering unparalleled flexibility and safety. These versatile structures provide a reliable solution for reaching heights efficiently, making them a preferred choice for professionals in various fields. With advancements in technology and materials, aluminum scaffolding towers continue to evolve, ensuring enhanced performance and durability on job sites.

Overview of Aluminum Scaffolding

Advantages

Aluminum scaffolding towers offer lightweight yet sturdy construction, making them easy to transport and set up quickly. Their corrosion-resistant properties ensure longevity, even in harsh weather conditions.

Versatility

Aluminum scaffolding is highly versatile, suitable for various applications such as construction, maintenance, and repair work. Its adjustable height and configuration options cater to different project requirements efficiently.

Durability

The durability of aluminum scaffolding towers is unmatched due to the material's inherent strength and resilience. They can withstand heavy loads while maintaining their structural integrity over prolonged periods.

Types of Aluminum Towers

Single vs. Double

Aluminum scaffolding towers come in two main types: single-width and double-width. Single-width towers are narrower, providing easy access to tight spaces, while double-width towers offer more stability and space for workers and equipment.

Folding and Mobile Benefits

Folding aluminum towers are convenient for transportation and storage due to their collapsible design. They are ideal for projects that require frequent movement. On the other hand, mobile aluminum towers feature wheels for mobility, allowing workers to easily reposition them without disassembling.

Stairway vs. Podium

Stairway aluminum towers have built-in staircases for safe vertical access, making them suitable for tasks that involve frequent height changes. In contrast, podium aluminum towers have a larger platform area, providing ample space for multiple workers and tools simultaneously.

Features of Aluminum Scaffolding

Lightweight

Aluminum scaffolding towers are known for their lightweight nature, making them easy to transport and maneuver on-site. The style scaffold frames crafted from aluminum offer high strength while remaining exceptionally light.

Corrosion-Resistant

One of the key advantages of aluminum scaffolding is its corrosion-resistant properties. Unlike steel scaffolds, aluminum does not rust, ensuring durability and longevity even in challenging weather conditions.

Easy Transportation and Assembly

The coupling pin features of aluminum scaffolding contribute to its ease of transportation and assembly. These pins allow for quick and secure connections between the different components, simplifying the setup process significantly.

Rolling Towers Explained

Definition

Rolling towers, also known as aluminum scaffolding towers, are versatile structures used in construction and maintenance tasks. They provide a stable platform for workers to perform tasks at height safely.

Mobility and Convenience

Rolling towers are designed with wheels at the base, allowing them to be easily moved from one location to another. This mobility feature enhances efficiency on job sites where frequent repositioning is required. Workers can quickly adjust the tower's position without dismantling and rebuilding it, saving time and effort.

Safety Features and Stability

These towers come equipped with safety features such as guardrails, non-slip platforms, and locking mechanisms to prevent accidents. The stability of rolling towers is ensured by sturdy construction materials like aluminum, which offers both durability and lightweight portability. This combination of safety features and stability makes rolling towers a reliable choice for working at heights.

Safety Measures for Towers

Training Importance

Proper training is crucial when working with towers. Employees should undergo comprehensive training sessions to understand safety protocols.

Regular mock drills and hands-on practice can significantly enhance employee skills in tower handling. This ensures a safe working environment.

Inspection Significance

Frequent inspections are essential to identify any potential hazards or defects in the tower structure. Inspections must be conducted by certified professionals.

Inspectors check for loose bolts, damaged components, and overall stability of the tower. Early detection through inspections prevents accidents and ensures structural integrity.

Harnesses and Guardrails Necessity

The use of safety harnesses and guardrails is non-negotiable when working on towers. Harnesses provide fall protection, reducing the risk of injuries.

Guardrails act as a barrier to prevent falls from elevated platforms. They offer an additional layer of safety for workers at heights.

Assembly Guidelines for Safety

Following Manufacturer Guidelines

When assembling aluminum scaffolding towers, always adhere to the safety standards provided by the manufacturer. These guidelines ensure that the tower is assembled correctly and securely. By following these instructions, you guarantee a safe working environment for everyone involved.

Step-by-Step Assembly Instructions

Begin by unpacking the tower from the package and laying out all components.

Fit tubing sections together using bolt clamps according to the manufacturer's specifications.

Ensure that all connections are secure and properly tightened to support the maximum load capacity.

Attach collar1 at appropriate heights to create stability for the platform solution.

Include safety features such as guardrails and non-slip surfaces for added protection.

Importance of Teamwork in Assembly

Having a team for assembly not only makes the process faster but also enhances safety measures. Each member can focus on specific tasks, ensuring that no step is overlooked or incorrectly executed. Working together promotes efficiency and accuracy in assembling the tower, reducing risks of accidents due to improper construction.

Usage Regulations for Workers

Legal Requirements

Workers using an aluminum scaffolding tower must adhere to strict legal regulations when working at heights. These regulations ensure their safety and the safety of others around them. Failure to comply with these regulations can result in severe consequences, including fines or even legal action.

Supervision Needs

Proper supervision is crucial when workers are utilizing the tower. Supervisors play a key role in overseeing the work being done, ensuring that all safety protocols are followed correctly. This supervision helps prevent accidents and ensures that tasks are carried out efficiently and effectively.

Safety Gear Importance

Wearing appropriate safety gear is non-negotiable when working on an aluminum scaffolding tower. Helmets, harnesses, and sturdy footwear are essential to protect workers from potential falls or injuries. Neglecting to wear this gear can lead to serious accidents and endanger the lives of those involved.

Maintenance Tips for Security

Importance of Regular Checks

Regular maintenance checks are crucial for ensuring the security and stability of aluminum scaffolding towers. By conducting routine inspections, potential issues can be identified early, preventing accidents and ensuring a safe working environment for workers. These checks should include examining the structural integrity, checking for loose bolts or fittings, and verifying the stability of the platform.

Cleaning and Storage Significance

Proper cleaning and storage of aluminum scaffolding is essential to prolong its lifespan and maintain its structural integrity. Cleaning removes dirt, debris, and other contaminants that could weaken the materials over time. Storing the tower in a dry, well-ventilated area helps prevent corrosion and damage from environmental factors. Disassembling the tower when not in use can prevent accidental falls or damage during storage.

Immediate Repairs for Damages

In case of any damages or signs of wear and tear on the scaffolding tower, immediate repairs are necessary to ensure continued safety. Any cracks, dents, or bent components should be addressed promptly to prevent further deterioration and potential hazards. Engaging with qualified professionals for repairs ensures that the tower remains secure and compliant with safety regulations.

Aluminum Scaffolding in Various Industries

Construction Applications

Aluminum scaffolding is widely used in construction projects for its lightweight yet sturdy properties. It allows workers to easily assemble and disassemble the scaffold, enhancing efficiency on-site. The ability to stabilize scaffolding at various heights ensures a safe working environment for construction teams.

The versatility of aluminum scaffold extends to its mobility, enabling easy scaffold moving when shifting work locations. With the option to add outriggers for increased stability, aluminum towers provide a secure platform for workers at elevated levels. This feature is particularly beneficial in construction sites where safety is paramount.

Maintenance Benefits

For maintenance work such as painting or repairs, aluminum scaffolding towers offer significant advantages. Their durability and resistance to corrosion make them ideal for outdoor projects like painting schools, churches, or colleges. Painters appreciate the ease of maneuvering these towers with casters, allowing them to reach different areas effortlessly.

The flexibility of aluminum scaffolding caters to various maintenance tasks, from changing light fixtures in schools to repairing roofs in churches. The secure scaffold connections ensure stability while working at heights, giving maintenance crews peace of mind during their projects.

Closing Thoughts

You've gained a comprehensive understanding of aluminum scaffolding towers, from their types and features to safety measures, assembly guidelines, and maintenance tips. These versatile structures play a crucial role in various industries, ensuring the safety and efficiency of workers at height. Remember to adhere to usage regulations and prioritize regular maintenance to guarantee a secure working environment for you and your team.

Incorporate these insights into your practices to enhance safety standards and streamline operations when working at heights. Stay informed about the latest developments in aluminum scaffolding technology to continuously improve workplace safety. Your commitment to following best practices will not only protect your team but also optimize productivity. Keep building safely!

Frequently Asked Questions

How can aluminum scaffolding benefit my project?

Aluminum scaffolding offers lightweight and durable solutions, making it easy to transport and set up on-site. Its corrosion-resistant properties ensure longevity, while its versatility allows for safe access at various heights.

What are the different types of aluminum towers available?

Aluminum scaffolding comes in various types such as single-width towers, double-width towers, folding base units, and stairway towers. Each type caters to specific project requirements, offering flexibility and safety features for different applications.

Are there specific safety measures to consider when using aluminum scaffolding?

Safety is paramount when working with aluminum scaffolding. Ensure proper assembly following guidelines, use stabilizers on uneven surfaces, conduct regular inspections, provide training for workers, and adhere to usage regulations to prevent accidents and ensure a secure work environment.

How should I maintain my aluminum scaffolding for long-term use?

Regular maintenance is crucial for the longevity of aluminum scaffolding. Inspect for damages or wear regularly, clean after each use to prevent debris buildup, store in a dry environment to avoid corrosion, lubricate moving parts as needed, and follow manufacturer's guidelines for upkeep.

In which industries is aluminum scaffolding commonly used?

Aluminum scaffolding finds applications in various industries such as construction, maintenance, painting, electrical work, event management, and more. Its portability, durability, and adaptability make it a preferred choice for professionals requiring safe access at elevated heights across different sectors.